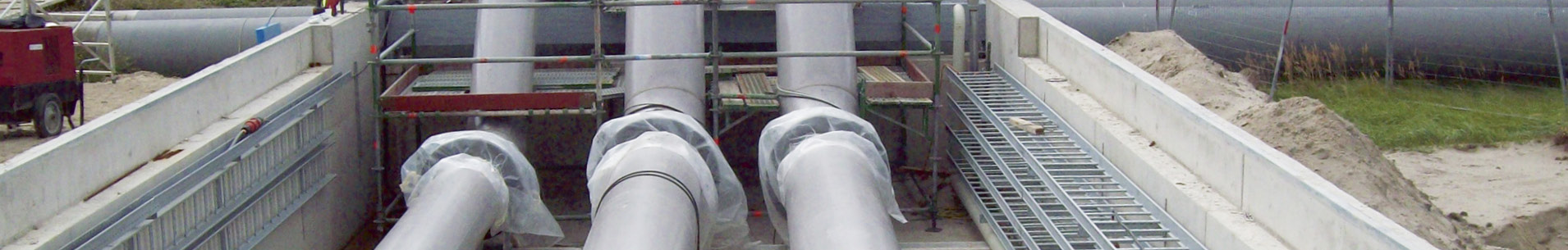

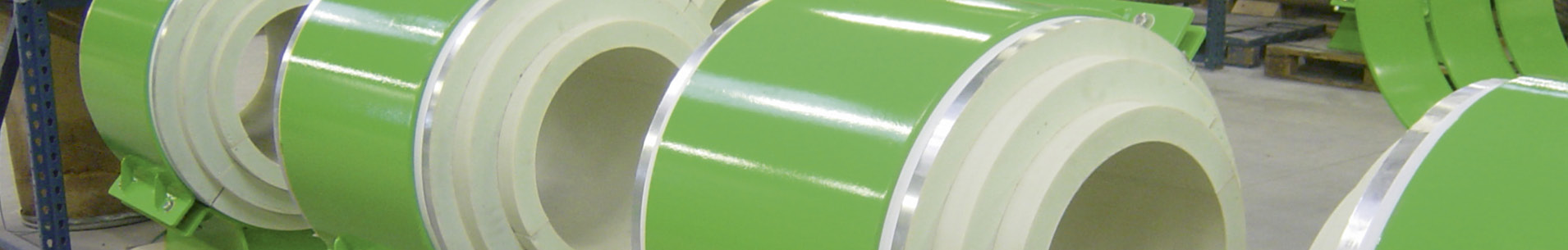

An important component of our final product is a steel

fabricated pipe support.

This is manufactured in a dedicated steel fabrication department. This department

utilizes a large number of overhead cranes up to a capacity of 10 metric tons.

This department is supported by plasma cutting, laser cutting, welding robots, grinding and cleaning

stations, CNC controlled rolling stations, CNC controlled press brakes, CNC controlled bending

equipment and CNC controlled milling stations.

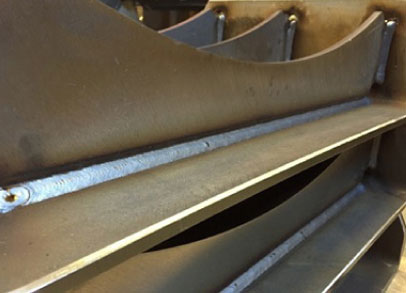

The welding department consists of a number of welding stations. Each station with qualified welders

and state of the art (pulse) welding machines. 4 Welding robots stations support this department.

Offline programming of welding robots reduces the down time of welding robots resulting in a

continuous operation.

The rolling department has 4 CNC controlled rolling equipment enabling rolling steel plate up to 40 mm

in thickness.

The cleaning department cleans steel components prior to further processing and after welding. A clean

working environment and clean components improve the quality of the end product.

As a result of a high degree of automation steel components can be manufactured efficiently against a

unbeatable quality.

-

-

keep it simple

-

-

-

-