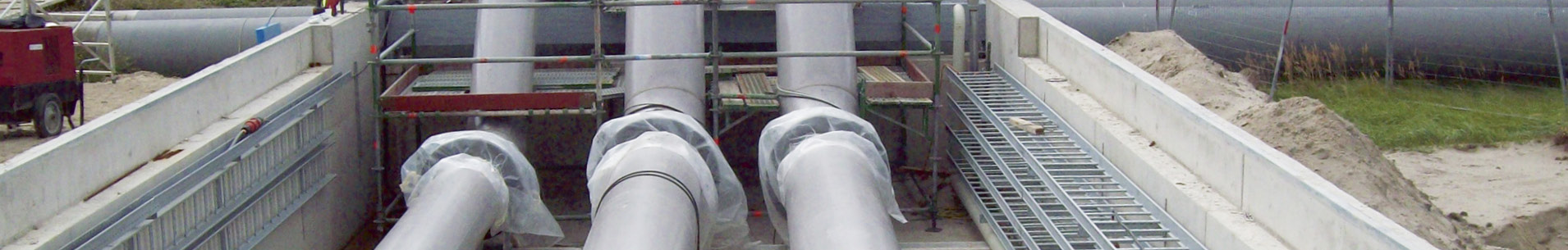

POWERFOAM™ cold/cryogenic pipe supports are

designed for low temperature piping systems.

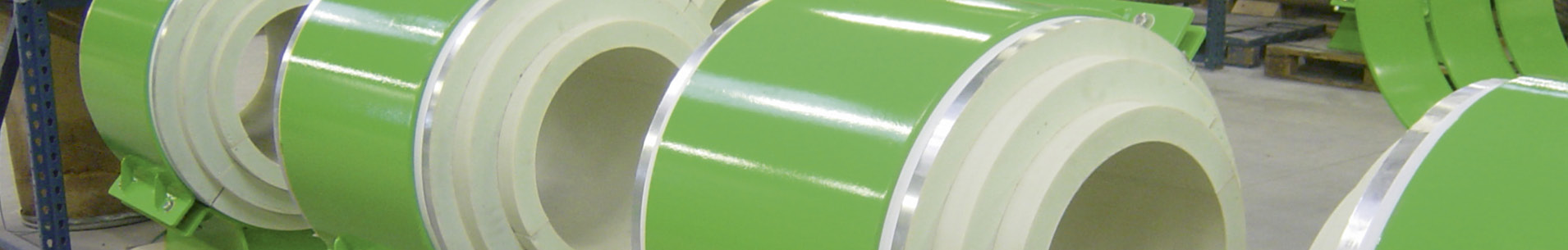

POWERFOAM™ is a high density Polyurethane in various densities; each with a

unique formulation that creates the outstanding characteristics of POWERFOAM™.

POWERFOAM™ is monolithically pressure moulded polyurethane manufactured in 180° sections

for each size combination. From ½” NPS up to 72”NPS. The result is an ultra high density skin on all

surfaces except vertical end. This creates a supreme quality product.

POWERFOAM™ High Density Polyurethane pipe supports fully comply to the latest Shell DEP and CINI

standards which are in use on a large number of sites worldwide. Many engineering companies have

updated their standards to reflect our specification for cold insulated pipe supports.

The densities of our High Density Polyurethane vary between 160, 224, 320 and 500 kg/m3. Each density

is colour codes for tracebility purposes. POWERFOAM™ has been tested in actual configuration

to obtain it’s thermal and physical performance data. Please contact our sales department for full

documentation.

Standardly a vapour barrier is factory applied to ensure an impeccable interface with the line insulation.

This vapour barrier can be a foil of various types or a mastic.

To ensure a good interface with the line insulation a protection shield is introduced; the material is

equivalent to the jacketing used on the line insulation.

Powerfoam™ supports are supplied pre-assembled.

Copied many times; not equaled.

-

-

copied many times; not equaled.

-

-

-