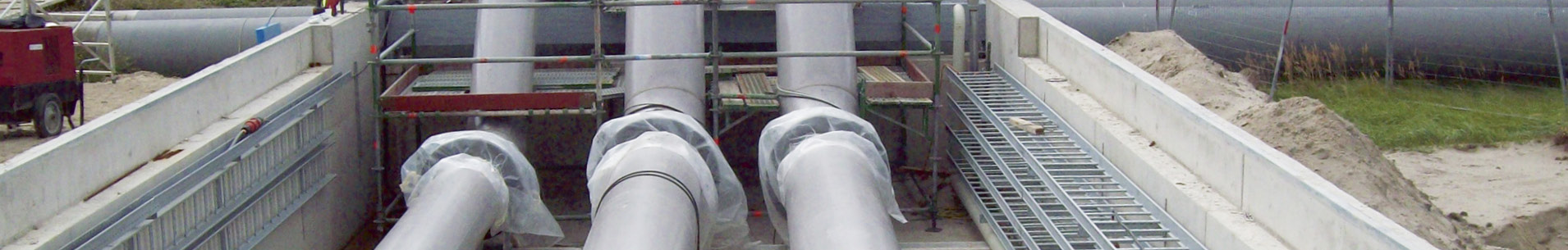

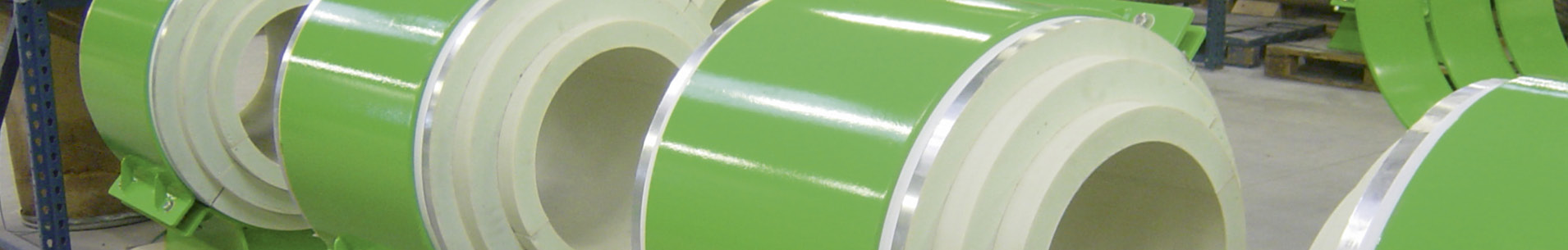

TIMTHERM® hot insulated pipe supports are designed for

high(er) temperature piping systems up to 1000°C.

The philosophy is to isolate the pipe in contact with the substructure.

Conventional pipe supports consist of a metal pipe support protruding through the insulation and

thereby forming a direct metal to metal contact between the pipe and the sub-structure.

Heatlosses are largely reduced resulting in a return on investment of a couple of years. This in

comparison with conventional clamped on or welded pipe supports in direct contact with the pipe.

In addition the root cause of corrosion under insulation (CUI) is largely eliminated.

Even high alloy steel supports are required due to the temperature of the pipe; sometimes even high

alloy spring and constant hanger assemblies are utilized.

TIMTHERM® insulated pipe supports have the following advantages:

- no hot spots in the line

- heatlosses are significantly reduced

- chances on stress corrosion cracking are significantly reduced

- easy installation by one (mechanical) contractor only

- simple pipe support design

- simple insulation configuration at support location

- economize on insulation thickness for total system

- temperature related problems are eliminated

-

-

lower your heatloss

at pipe support location -

-

-